SP series in the spotlight

The sales of REDEL SP Series plastic connectors have shot up during the last few years. The success story started in 2012, thanks to combined efforts of several LEMO Group entities.

To say that REDEL SP connectors have been a success would be quite an understatement. The series – one of the two circular “ all-plastic ” connectors produced by the LEMO Group – has seen its sales explode by 600% these last five years, North America being its largest market, with Japan and North Europe runners-up.

The success of the SP Series does not only rest on the legendary quality and reliability of LEMO solutions. It is also thanks to a combination of unique product qualities, resulting from two years of research.

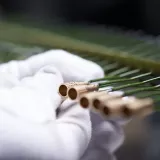

Firstly, SP (Small Plastic) connectors stand out due to their compact design. Their unique internal latch mechanism is very space efficient and therefore they can accommodate a higher contact density in the same footprint as the Redel P standard with up to 22 contacts.

Their housing is made of FDA certified PPSU (polyphenylsulfone), five times lighter than steel and highly resistant to sterilisation cycles, cleaning agents and high temperatures. The patented internal latch mechanism offers even higher protection from liquids (sterilisation and splashes), and, at the same time, higher resistance to mechanical shock and impact.

Ease of use is another distinctive quality of the SP range, which is particularly pertinent in the medical field, as easy handling is a prerequisite rather than a benefit. In addition to its ergonomic design and intuitive Push-Pull latch system, there are three guide keys, enabling “ blind mating ” as well as colour coding for instant identification of what connects where. The sales of REDEL SP Series plastic connectors have shot up during the last few years. The success story started in 2012, thanks to combined efforts of several LEMO Group entities. Close-up on a solution that has become a reference in the medical field. High density, compact design, resistance to sterilisation cycles and ease of use : everything was there to convince medical technology companies. Combined with a dedicated high-performance cable – NORTHWIRE’s BioCompatic, for example – SP connectors offer THE ideal solution for hospital environments. These characteristics have managed to convince other demanding sectors, such as test & measurement, automotive and industrial applications. It embodies the extraordinary experience of REDEL in plastic connectors. An experience rooted in “ Made in Switzerland ”. In fact, REDEL was created in 1986, when LEMO acquired, in the Swiss Jura region, the injection moulding and screw-machining units of a typewriter factory that went bankrupt. It was a winning investment : relying on its vast know-how in micromechanics and injection moulding, the subsidiary has never stopped developing. Internally, it has become the Group’s “ centre of excellence ” for precision machining. Externally, it has positioned its brand as a reference for the medical sector.

Before the SP Series, the P Series has already left a strong impression. Designed since 1984 in 3P size, and then in 1P (1988), it has already been recognised for its innovation and superior quality. As with any product that shapes the market, copies were inevitable, but this has not deterred the company. As they say, “ imitation is the sincerest form of flattery ” and it is this encouragement that drives the development cycle on. REDEL has proven – and continues to do so – that plastic deserves to be at the high end of the market.

The SP Series’ journey has not come to an end yet. LEMO engineers are currently working on developing new variants. With even higher performance and resistance. Even more SP, even more spectacular.